-

Products

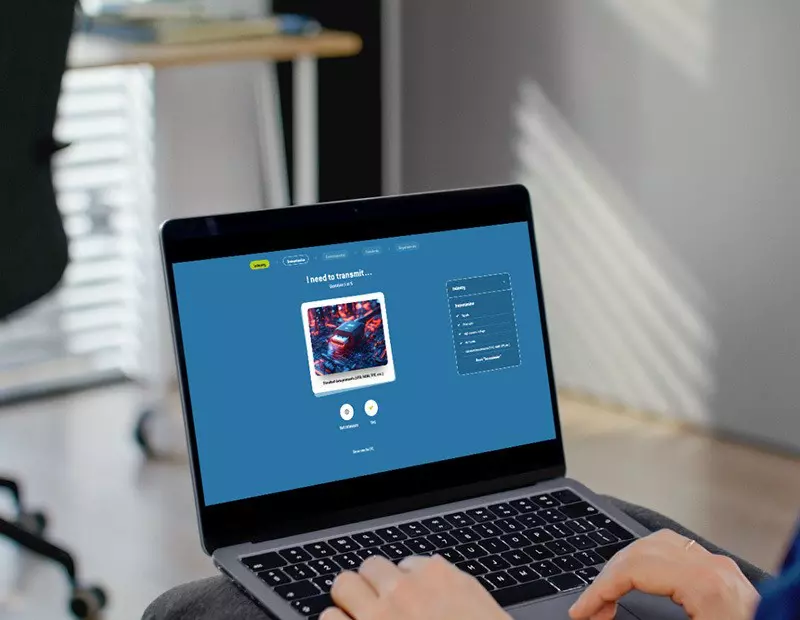

Find your matching solution Your suitable product category in a few clicks.

- Technologies

- Industries

- Service

- Company

Consistent performance and a high degree of failure protection are of vital importance in medical technology. As an interface specialist, we develop and produce custom systems and standard solutions for your medical applications. From MRI equipment to endoscopy, we design all our connectors in compliance with the strictest regulations and applicable standards.

Mark Bingham (Product Manager) informs how ODU supports the implementation of the MDR.

In contrast to the Medical Device Directive (MDD), which was previously valid in the EU and had the character of a directive, the Medical Device Regulation (MDR), as a binding legal standard, places high demands on device manufacturers with regard to production, documentation and, above all, electrical safety. The IEC 60601 standard contained in the MDR also poses particular technical challenges for manufacturers. ODU supports its customers in many ways in complying with the MDR regulations.

Manufacturers must provide comprehensive technical documentation containing all information on the design, manufacturing relevance, safety, performance and clinical evaluation of the device.

A systematic approach to the identification, assessment and control of risks associated with the use of electrical equipment. The risk assessment for each product group is carried out in accordance with ISO149791.

Changes to products or processes that affect quality require classification into two types: "major" for significant changes that require approval from authorities, and "minor" for minor changes that only need to be documented and may require general notification.

For carcinogenic, mutagenic or reprotoxic substances (CMR) and substances with endocrine disrupting features, a maximum limit of 0.1% by mass (w/w) applies. Justification is required for higher levels and the presence of CMR substances must be labeled on the products.

In the frame of the Unique Device Identification (UDI), every medical device must have a unique label for identification. This code enables the exact traceability of a product back to the manufacturer.

Among other things, the MDR requires the manufacturer of a medical device to provide complete documentation of its work. This also includes the archiving of documents from upstream suppliers. ODU guarantees complete data storage in accordance with customer requirements.

Outstanding contact resistance with more than 100,000 mating cycles, high-speed data transmission, easy cleaning, non-magnetic, silicone overmolding and many other individual requirements: Thousands of customers worldwide rely on this. ODU is your partner for the reliable transmission of signals, power, high current, high voltage, HF signals (coax), medical gases and liquids, data rates and fiber optics.

Decades of experience in the medical industry combined with state‐of‐the‐art technology ensure we can develop your connectors to perfection. Whether in diagnostics, therapy, hybrid operating rooms or patient monitoring – our products stand for consistent failure protection and reliability in everyday medical applications. We create quality in accordance with:

Our connectors, cables, and housings are characterized by extreme temperature and chemical resistance – and guarantee reliable tightness, including in compliance with high protection classes.

Sterilizable and disinfectable

Autoclavable at up to 134 °C and 3 bar

Easy cleaning of all surfaces

Vibration resistant

Use of biocompatible materials

Antimicrobial versions with plastic connectors available

We offer robust complete solutions for optimal haptics, hygiene, and durability. Autoclavable and tested in accordance with DIN EN ISO 10993-5.

At ODU, you receive your individual system solutions from a single source: from planning, development and documentation to the production and finishing of the products. During the development and manufacturing process, the products are comprehensively tested for durability and reliability in our in-house laboratory. This saves you time and money, while we can guarantee the highest quality.

Our modern production sites in Europe, Asia and the USA enable short supply chains and low dependence on third-party suppliers. We attach great importance to a high level of vertical integration and ultra-modern and sustainable production processes, such as surface treatment with chrome VI-free processes.

Many well‐known customers put their trust in high‐performance connector solutions from ODU: Whether for clinics, medical, and dental practices or home care, we develop custom solutions of the highest quality.

“In magnetic resonance imaging (MRI), it is imperative that the connectors we use can guarantee a high number of mating cycles while being absolutely non‐magnetic. […] It is especially in cases such as these, when special solutions are needed, that ODU supports us with the necessary technical flexibility and problem‐solving expertise.”

Read more (PDF 137 KB)“Thanks to their extensive experience and expertise in the conceptual design of connectors, we were able to develop an optimized and customized solution with ODU.”

Read more (PDF 244 KB)“When we needed a lightweight connection including cables, we benefited from ODU’s high vertical range of manufacture and expertise in cable assembly.”

Read more (PDF 290 KB)"ODU has met our demand for maximum reliability and safety, as well as ensuring intuitive and safe handling, by providing an optimal solution that perfectly matches our product."

Read more (331 KB)“Brumaba and ODU are similar in many ways. Aside from the fact that both companies are family businesses, it’s our highly meticulous nature and high degree of innovation that bring us together. We want to give our customers the best possible solution and an ideal product.”