-

Products

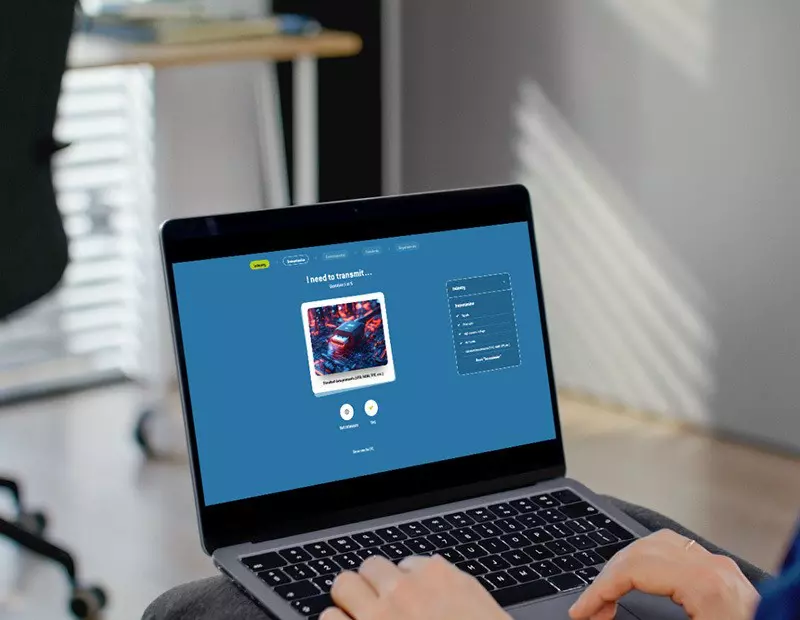

Find your matching solution Your suitable product category in a few clicks.

- Technologies

- Industries

- Service

- Company

Get everything you need from a single source! To create a connector system that is right for you, we ensure the optimal interaction of three central components: the ODU Connectors, the optimal termination technology and a suitable cable. For example, for an application involving high currents or temperatures as well as high-speed data transmission, whereby reliable sealing is also important, it is not enough to simply offer a high-quality connector – and disregard the associated termination technology or cable assembly. A connector can only meet the requirements for your application in combination with the right cable.

Solutions for harsh environments and a high number of mating cycles, as well as for standard requirements.

Flexible overmouldings – as a special feature in the field of cable assembly, we offer overmouldings for prototypes and small series in custom shapes. We can thus ensure extreme flexibility with short lead times and low prices. We ensure worldwide availability thanks to state-of-the-art manufacturing facilities at all locations.

We realise in-house cable assemblies for

Rapid available complete solutions in 100% tested quality and any length with no minimum order quantity.

Whether you need standard products or customised solutions, with ODU you get your finished connector from a single source. From concept to development to the finished system solution – you deal with the same person at ODU through all production steps to ensure a quick and efficient solution.

Customised solutions for your medical technology applications that guarantee permanent performance and reliable failure protection.

Complete system solutions based on your specifications – for reliable inspections and resilient results in test and measurement technology.

Reliable connector solutions that meet your requirements – even under extreme environmental conditions and high loads.

Through our many years of experience, we implement high-quality cable assemblies that undergo a 100% final inspection. We produce moulded connectors using the silicone, hotmelt or high-pressure processes – precisely tailored to your requirements. We thus produce reliable and durable complete systems in partnership with leading cable manufacturers. Furthermore, you always have a single point of contact – from the conceptual design to the final implementation.

To ensure that we can quickly build samples or prototypes, we carry a large selection of cables and third‐party products in stock, which are immediately available for further processing. This saves you time and resources during the design and implementation phases of your projects.

We work with you to develop a solution that perfectly meets your requirements. From planning and production to cable assembly, we combine all competencies under one roof and can also implement customised solutions for your project.

Our circular connectors, modular connectors, and customised solutions are available with cable assembly. We also offer individually assembled electrical contacts.

If an ODU Connector is used at one end of the cable, we generally assemble all the associated products. This means we can also assemble third‐party products.

Above all, cost and time savings! You deal with the same person at ODU when ordering both connectors and cables – for fast delivery with zero stress.

All standard cables are available “off the shelf” at ODU and can be found in our Standard Cables and Accessories catalogue.

In addition to fast quotations, we also guarantee rapid availability with our standard cables, for example for sampling.

Cables other than those listed in the catalogue can be used on request or to meet specific requirements. If necessary, we can find special cable solutions for your custom projects thanks to our close partnerships with leading cable manufacturers.

From small batches to high-volume production, anything goes! Thanks to our dedicated sampling process, we can provide prototypes and functional samples with very short lead times. Thanks to our high vertical range of manufacture, we can produce and assemble everything in‐house – from a single source.

If a connector is moulded, then the design can be optimally adapted to the connector geometry and the cable jacket. Customised geometries and colours are also possible with overmouldings. In addition, they provide improved strain relief and kink protection. In terms of the overall process, these solutions are also more cost-effective than using conventional grommets.

Yes, even for small batches, customised overmouldings are available at cost-effective prices.