-

Products

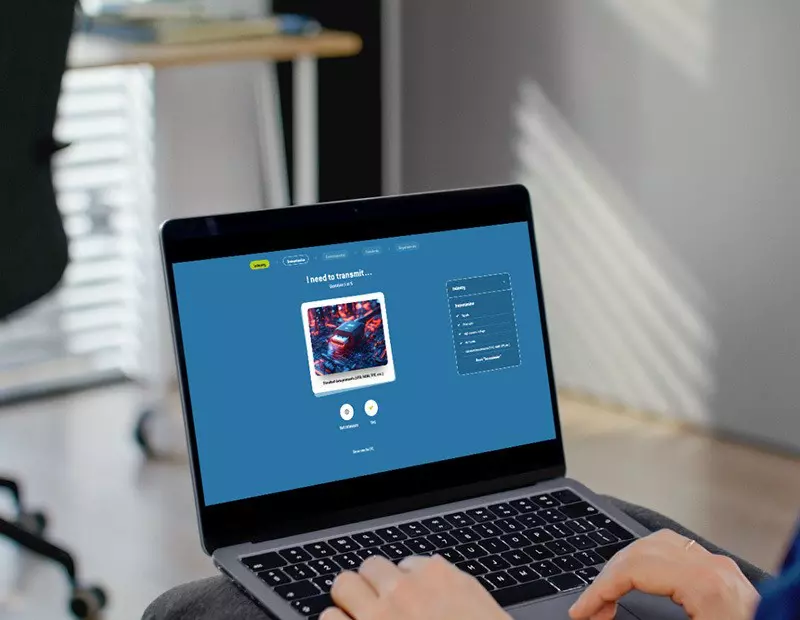

Find your matching solution Your suitable product category in a few clicks.

- Technologies

- Industries

- Service

- Company

ODU's Expanded Beam solutions guarantee the highest data rates and transmission speeds even under harsh conditions. The durable fiber optic solutions with expanded beam technology maintain their high performance even up to 100,000 mating cycles.

How does it work?

Due to the beam expansion via a special lens, the light is transmitted error-free from one contact to the lens of the contact in the counterpart. Expanded Beam technology thus guarantees reliable and interference-free transmission even under adverse conditions.

As there is no direct contact between the contact ends, Expanded Beam connections are insensitive to soiling and are easy to clean. No cleaning is required under normal conditions. This ensures reliable transmission without damage.

| ODU MEDI-SNAP® | ODU MINI-SNAP® Series K | ODU AMC® Series T | ODU-MAC® White-Line/Silver-Line | |

|---|---|---|---|---|

| Mating cycles | 2,000 | 5,000 | 5,000 | 50,000 |

| IP Rating | IP64 | IP68 | IP6K9K | IP50 - IP67 |

| Temperature | -40°C / +85°C | -40°C / +85°C | -40°C / + 85°C | -40°C / +85°C |

| Locking system | Push-Pull | Push-Pull |

Push-Pull Threaded | Spindle locking / Transverse locking / Lever locking |

| Housing material | Plastic | Metal | Metal | Metal / Plastic |

| Special feature |

Light weight Non-magnetic |

Smallest footprint (OD 16.2mm) | Ruggedized |

Automatic docking / Manual mating Hybrid Non-magnetic |

Expanded beam technology uses a single lens contact to expand the light beam, enabling error-free transmission of light from one contact to the lens of the counterpart. This ensures reliable and interference-free data transmission even under adverse conditions.

The Expanded Beam technology is characterized by high robustness, requires no cleaning under normal conditions, enables up to 100,000 mating cycles and offers higher attenuation properties even under harsh conditions compared to a physical ferrule solution.

It is suitable for applications in harsh environments, both indoors and outdoors. The technology is particularly suitable for hybrid connector requirements, as they can benefit from a small pole pattern.

ODU Expanded Beam systems are designed for up to 100,000 mating cycles, which ensures a long-lasting connection.

The insertion loss is ≤ 1.5 dB per contact side, which ensures efficient signal transmission.

The return loss is ≥ 32 dB (multimode), which contributes to a high signal quality.

ODU's Expanded Beam technology is suitable for multimode. For singlemode, please select Expanded Beam Performance.

The Expanded Beam systems are designed for a temperature range of -40 °C to +85 °C, which allows them to be used in various environments.

No cleaning is required under normal conditions. However, the connections are easy to clean if necessary, as there is no direct contact between the contact ends, which increases their resistance to soiling.

We work with you to develop a solution that perfectly meets your requirements. From planning and production to cable assembly: We combine all competencies under one roof and can also implement customized solutions for your project.