-

Products

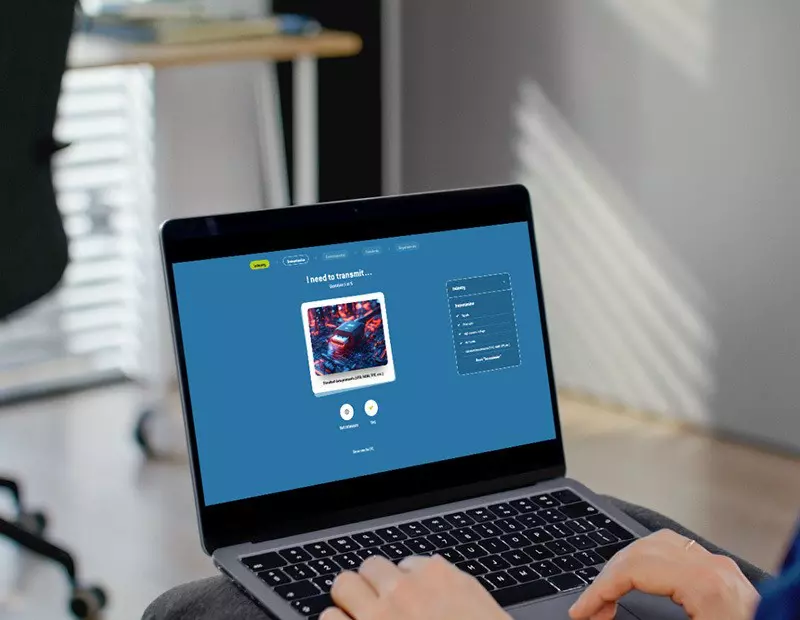

Find your matching solution Your suitable product category in a few clicks.

- Technologies

- Industries

- Service

- Company

For the BlueFlow® heater from GÜNTHER Heisskanaltechnik, ODU developed a new, customised solution with a ceramic insulator that can withstand temperatures in excess of 300 °C and has a load capacity up to 230 V. It also features push-pull locking for direct connection to the heater.

As a result, the heating system is able to adjust the heating power to exactly match the demand in each section of the nozzle and thus achieve a homogeneous temperature in the hot‐runner nozzle.

The autonomous cleaning robot ADLATUS follows the trend towards digitization and automation in industry. When it needs to charge, it automatically returns to its docking station, in which a robust ODU-MAC® Silver-Line docking solution is installed. This is pre-wired at ODU and can transmit fluids, power and signals thanks to its modular design.

The cleaning robot supports workers by performing physically arduous or monotonous cleaning work; for example, in supermarkets, hospitals or airports. It can move independently, even over several floors, by communicating with elevators.

The electric Surfboard Hydrofoil from Lift Foils requires a connection with a high current-carrying capacity. Due to its maximum speed of 40 km/h, the connector must also be shock, vibration and corrosion resistant, and sealed to prevent the ingress of water. In this case, the ODU LAMTAC® with a current-carrying capacity of up to 2,400 A proved to be the optimal solution.

A custom solution based on ODU LAMTAC® Contact Technology serves as the interface between the speed controller, motor and battery. The ODU MINI-SNAP® Series K is also used for the secure transfer of sensitive data between the battery and the control unit. This particular solution is characterised by extreme reliability, a robust metal housing and a high degree of watertightness.

The TARM (Telescopic Articulated Remote Mast) is located in the RACE test facility operated by the British company UKAEA. Operated by remote control, TARM can be deployed inside the fusion reactor to perform maintenance work in extremely challenging environments. High radiation doses and temperatures as well as limited access pose a great challenge for this robotic system. It must remain operable at all times without failure.

TARM consists of a vertical telescopic mast and a horizontal telescopic boom. A connector solution consisting of the ODU-MAC® Silver-Line and the ODU‐MAC® White‐Line is installed on each of the three joints of the telescopic boom. This combination optimally meets the customer’s requirements thanks to a modular design for the transmission of different media, high packing density, data and fibre-optic transmission, as well as the use of highly radiation-resistant LCP insulators.

Inside the snow groomer’s drive system, ODU lamella contacts form an interface between the inverter and the electric drive. For this customer‐specific solution, the high‐current ODU LAMTAC Contacts were integrated into the smallest of construction spaces.

The angled ODU pin contact makes contact with an ODU TURNTAC® Socket and thus connects to the modules of battery storage systems. The ODU Product, which is manufactured including the cable assembly, is easy to assemble. Additional protection against unintentional demating ensures perfect connections.

The ODU LAMTAC® Socket with male thread is suitable for easy mounting on busbars. This contact system ensures optimal transmission properties and serves as an ideal connection point in decentralised power supply systems, as well as for rapid connections in testing facilities.

From tool‐change systems and factory automation to docking devices in testing facilities and industrial robot systems – the reliable docking connectors in the ODU DOCK series have proven themselves in diverse applications. Their robust design and excellent guiding properties make them the perfect connection component.

A customised version of an ODU SPRINGTAC® Contact was developed for the transmission of welding current in a tool-change system. An intelligent crimp termination system ensures maximum flexibility in the tiniest of installation spaces – as well as one million mating cycles.

A rebreather system circulates breathing gas around the diver allowing them to “re-breathe” the air, instead of exhaling gas straight out into the water as in a scuba system. This makes rebreathers highly efficient as well as silent and bubble-free, making the diver a natural part of the underwater environment.

On this high-end rebreather, customized ODU MINI-SNAP® connectors ensure a safe connection under demanding conditions. The screw locking avoids accidental demating and the tightness is guaranteed by two O-rings.