ODU TURNTAC®

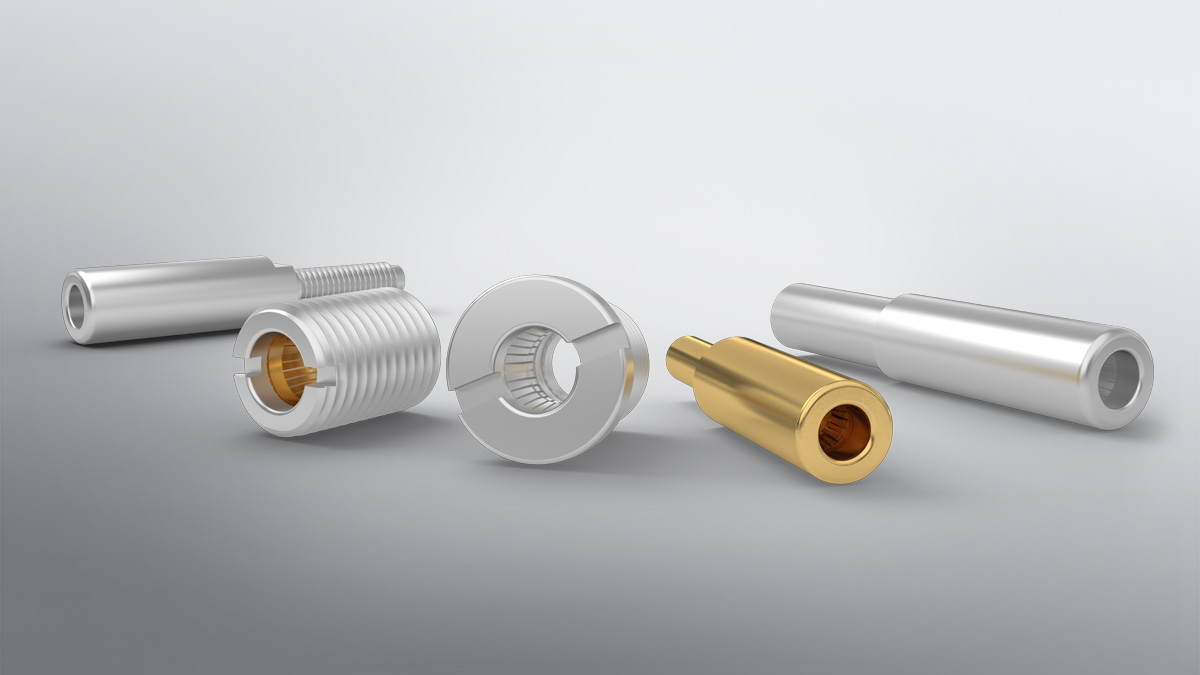

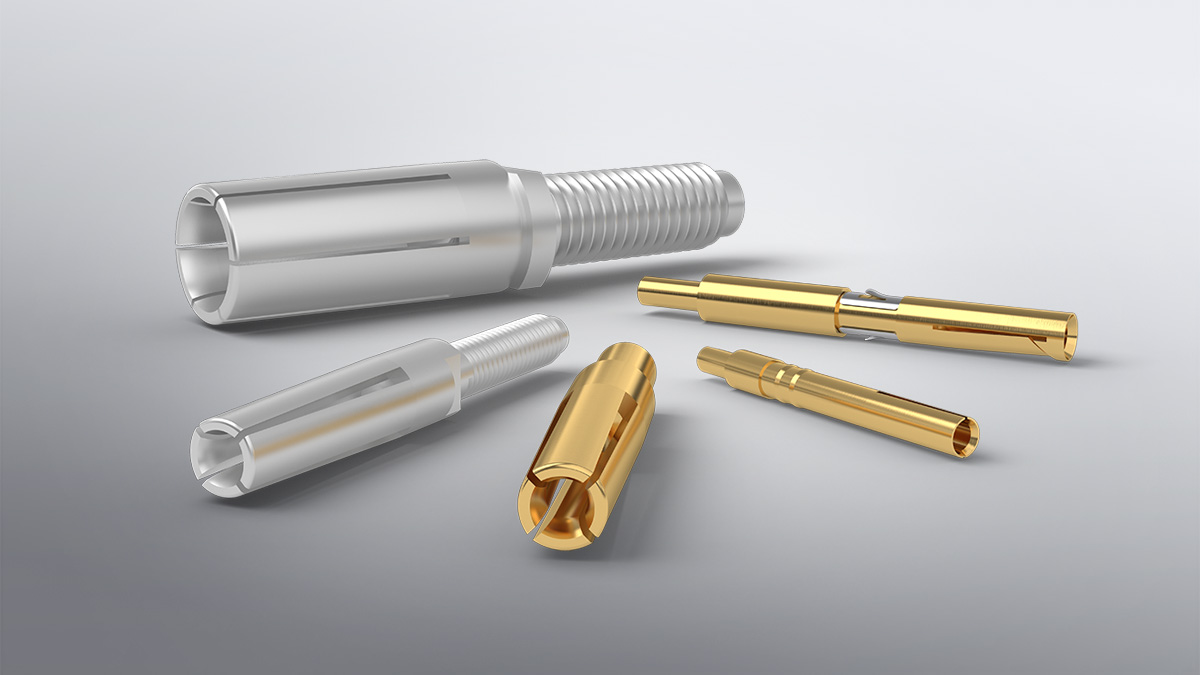

Contacts in turned and slotted version

Extremely robust

Elastic contact fingers

Cable assembly included

Up to 10,000 mating cycles

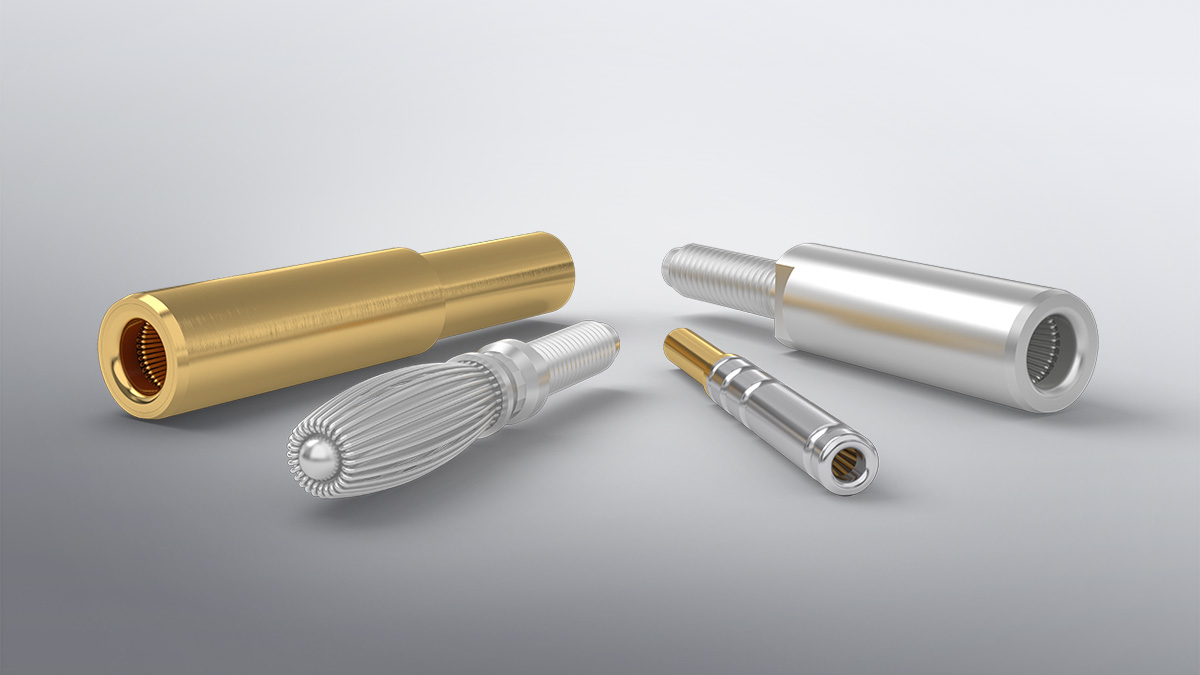

The ODU TURNTAC® Contact System ensures reliable connections even under high loads thanks to the elastic contact fingers. You can choose between different sizes in order to customize the contacts to your application. Even with particularly small contact diameters, ODU TURNTAC® convinces thanks to its durable contact properties.

- Low and stable mating and demating forces

- Tiniest dimensions possible, down to 0.3 mm contact diameter

- Mating possible at an angle of up to 5°

- Up to 10,000 mating cycles

Compare products

ODU LAMTAC®

|

ODU SPRINGTAC®

|

ODU SPRINGTAC® Flatsocket

|

ODU TURNTAC®

|

|

|---|---|---|---|---|

| Primary attribute | High temperature & current | High mating cycles | High mating cycles | Rugged |

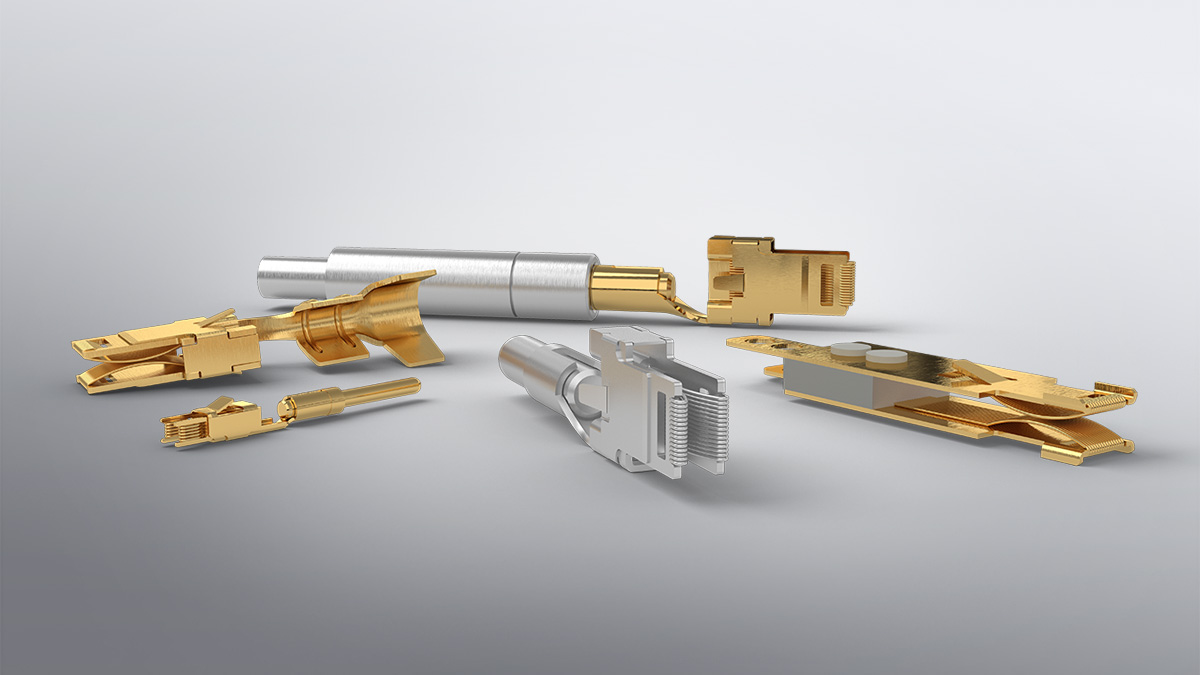

| Contact technology | Lamella technology | Springwire technology | Springwire technology | Turned, slotted contacts |

| Contacting | 19 lamella louvres with 2 contact points each (size ∅ 6 mm) | 44 wire springs (size ∅ 6 mm) | 30 wire springs (size 6.3 x 0.8 mm) | 4 contact fingers (size ∅ 6 mm) |

| Nominal current | 115 A (size ∅ 6 mm) | 110 A (size ∅ 6 mm) | 27 A (size 6.3 x 0.8 mm) | 100 A (size ∅ 6 mm) |

| Angular misalignment | +/- 1° | +/- 1° | +/- 5° * | |

| Mating cycles | > 10,000 | > 100,000 | > 50,000 | > 10,000 |

| Temperature range standard version | -40 °C to 150 °C | -40 °C to 125 °C | -40 °C to 125 °C | -40 °C to 125 °C |

| Contact size** | from ∅ 1.5 mm | from ∅ 0.76 mm | from 0.64 x 0.64 mm | from ∅ 1.5 mm |

| Standard plating | Ag / Au | Ag / Au | Ag / Au | Ag / Au |

| Crimp termination | • | • | • | • |

| Screw termination | • | • | • | • |

| For busbars (through-hole design) | • | • | •*** |

* Max. 5° misalignment in the assembly position with a correspondingly designed contact chamber

** Other sizes on request

*** Optional

Expanded Beam Performance

Discover the new diversity now!

The robust option when it comes to electrical contacts

Learn about the key benefits of our turned and slotted ODU TURNTAC® Contacts at a glance. This universal contact system combines the very best contact properties and high quality with economic prices. Thanks to its extraordinarily robust design, this contact system excels if misalignment occurs on mating, even in harsh environments.