-

Products

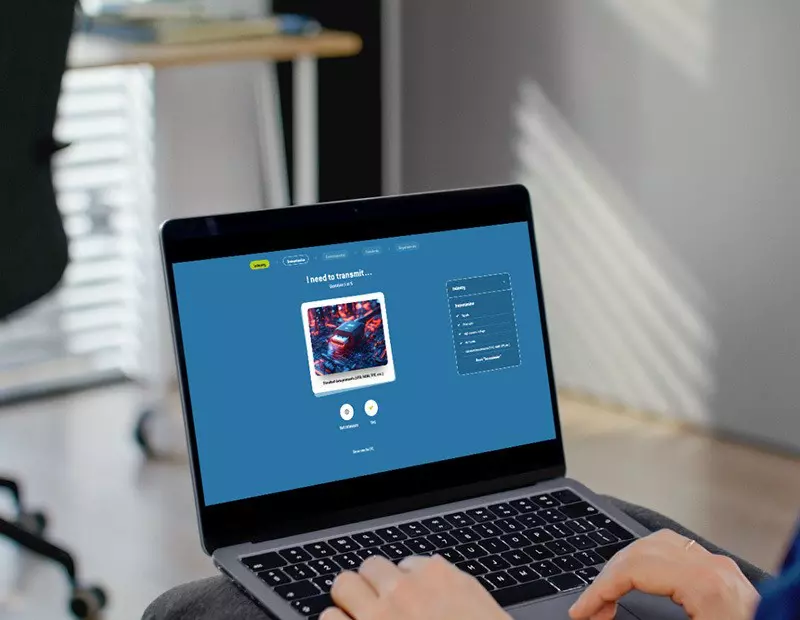

Find your matching solution Your suitable product category in a few clicks.

- Technologies

- Industries

- Service

- Company

From tool‐change systems and factory automation to docking devices in testing facilities and industrial robot systems – the reliable docking connectors in the ODU DOCK series have proven themselves in diverse applications. Their robust design and excellent guiding properties make them the perfect connection component.

A customized version of an ODU SPRINGTAC® Contact was developed for the transmission of welding current in a tool‐change system. An intelligent crimp termination system ensures maximum flexibility in the tiniest of installation spaces – as well as one million mating cycles.

The MEDUMAT/MEDUVENT ventilator includes ODU SPRINGTAC® contacts in the docking station with charging interface (Life Base) and ODU MEDI‐SNAP® as an interface between the various SPO2 and ECG devices and the power supply.

The ODU receptacles that are used achieve 2 MOOP & 2MOPP (Means of Operator Protection & Patient Protection) and are thus compliant with IEC 60601-1. Thanks to their interface function, they can also withstand a high number of mating cycles.

ODU SPRINGTAC® Contacts are used to supply power to operating table and couch systems. Maximum failure protection and reliable performance are essential in medical technology. Thanks to their high reliability and durability, as well as their current‐carrying capacity, the ODU contacts form a perfect connection between the table and the battery unit.

Dental treatment units require many different interfaces to meet a wide range of requirements. ODU SPRINGTAC® Contacts provide optimum functionality as a high‐performance interface between the motor and instrument hoses. The ODU Connector System is particularly suitable for such applications due to its extremely high contact safety.