-

Products

Find your matching solution Your suitable product category in a few clicks.

- Technologies

- Industries

- Service

- Company

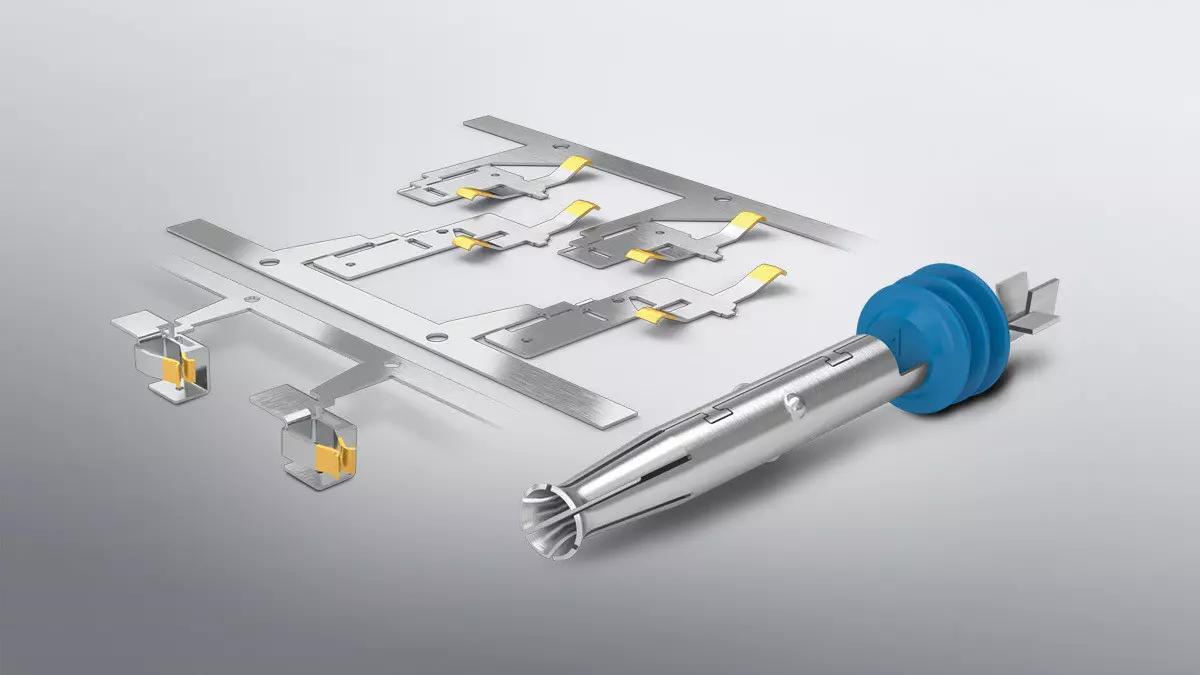

ODU SPRINGTAC® Flatsocket

Flatsockets with springwire technology

Stable contact resistance

Springwire technology

Cable assembly included

Up to 50,000 mating cycles

The ODU SPRINGTAC® Flatsocket with springwire technology is ideal for sensitive measurement tasks – especially in the field of test and measurement technology. Even during tests with high current loads, the socket ensures reliable results – with stable resistance values even during a high number of test cycles. Thanks to the compact design you can use the flatsocket for any common grid size.

- Suitable for a high number of test cycles

- Versions for 2 and 4‐wire measurements (Kelvin measurements)

- Ideal for flexible test adapters and replacement inserts

- High current‐carrying capacity

Compare products

ODU LAMTAC®

|

ODU SPRINGTAC®

|

ODU SPRINGTAC® Flatsocket

|

ODU TURNTAC®

|

ODU STAMPTAC®

|

|

|---|---|---|---|---|---|

| Primary attribute | High temperature & current | High mating cycles | High mating cycles | Rugged | For high volumes |

| Contact technology | Lamella technology | Springwire technology | Springwire technology | Turned, slotted contacts | Stamped contact technology |

| Contacting | 19 lamella louvres with 2 contact points each (size ∅ 6 mm) | 44 wire springs (size ∅ 6 mm) | 30 wire springs (size 6.3 x 0.8 mm) | 4 contact fingers (size ∅ 6 mm) | 8 contact fingers (size ∅ 6 mm) |

| Nominal current | 115 A (size ∅ 6 mm) | 110 A (size ∅ 6 mm) | 27 A (size 6.3 x 0.8 mm) | 100 A (size ∅ 6 mm) | |

| Angular misalignment | +/- 1° | +/- 1° | +/- 5° * | ||

| Mating cycles | > 10,000 | > 100,000 | > 50,000 | > 10,000 | > 10,000 |

| Temperature range standard version | -40 °C to 150 °C | -40 °C to 125 °C | -40 °C to 125 °C | -40 °C to 125 °C | -40 °C to 105 °C |

| Contact size** | from ∅ 1.0 mm | from ∅ 0.76 mm | from ∅ 0.64 x 0.64 mm | from ∅ 1.5 mm | ∅ 3 mm & ∅ 6 mm |

| Standard plating | Ag / Au | Ag / Au | Ag / Au | Ag / Au | Ag |

| Crimp termination | • | • | • | • | • |

| Screw termination | • | • | • | • | |

| For busbars (through-hole design) | • | • | •*** |

* Max. 5° misalignment in the assembly position with a correspondingly designed contact chamber

** Other sizes on request

*** Optional

Expanded Beam Performance

Discover the new diversity now!

Maximum reliability, precisely where it is needed

ODU SPRINGTAC® Flatsockets are the perfect, long‐lasting counterparts to traditional flat plug‐in contacts, especially for all manner of tasks in test and measurement technology. Their low, stable resistance values make them ideal for sensitive measurement tasks, as well as for tests in which high current‐carrying capacities are required.