-

Products

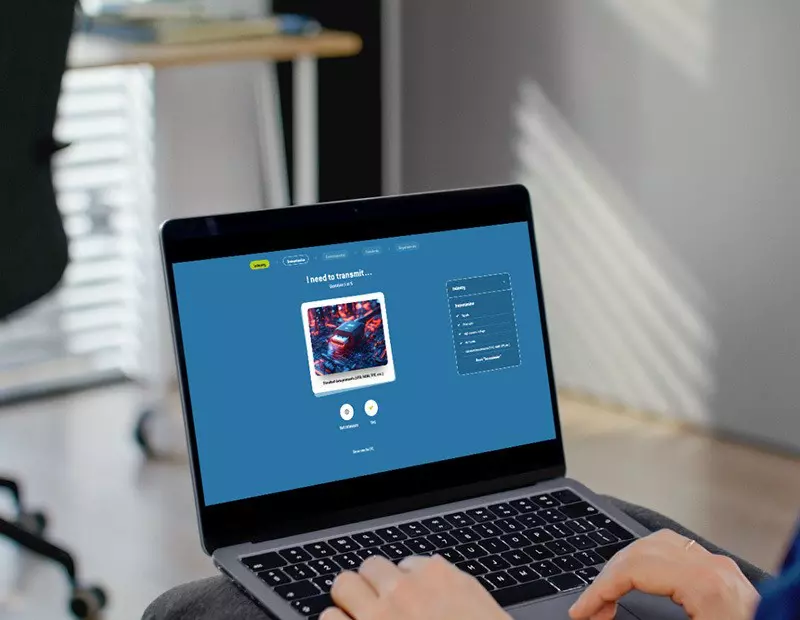

Find your matching solution Your suitable product category in a few clicks.

- Technologies

- Industries

- Service

- Company

Hygiene and resilience for medical technology – applications in medical technology must meet special hygienic and mechanical requirements, which is why we have developed a range of Silicone-overmolded System Solutions. Thanks to their non‐sticky surface and other properties, they are easy to clean, steam‐sterilizable, flexible, insensitive to extreme temperatures, and tested in accordance with DIN EN ISO 10993-5. This makes them a hygienic and robust solution for everyday medical use.

To meet medical requirements, we offer customized Silicone-overmolded System Solutions consisting of connectors, overmolded parts, and cables, including assembly and optional laser marking.

The specially developed surface of the cable and overmolding has a pleasant feel and prevents stickiness and the stick‐slip effect, even after continuous use. In combination with the smooth transitions to the overmoldings, the non‐sticky surface makes the cables extremely easy to clean – and thus ensures maximum hygiene for medical applications.

We offer Silicone-overmolded System Solutions as a flexible complete system consisting of connectors, cables with matching assembly, as well as the overmolding and optional labeling.

The smooth surface prevents the stick‐slip effect, guarantees easy cleaning, and complies with current hygiene standards. The system can withstand up to 500 autoclaving cycles.

Hygiene as a benchmark for the medical industry: Our Silicone-overmolded System Solutions are permanently compatible with both manual and mechanical cleaning methods. Even more important, however, is their thermal stability during steam sterilization – for up to 500 autoclave cycles. The surface properties remain unchanged, permanently.

A particularly important feature of our Silicone-overmolded System Solutions is the kink protection, which is provided by means of a sliding overmolding. This guarantees high bending fatigue strength for the cable and overmolding, while eliminating any edges which could potentially harbor unhygienic contaminants. The adhesion between the cable jacket and the overmolding remains durable even after steam sterilization and extreme stresses.

why Silicone-overmolded System Solutions are ideal for use in the field of medical technology:

Endoscopy is one of the most important application areas for our Silicone-overmolded System Solutions. The use of highly flexible and autoclavable, skin-friendly, and slippery materials is of particular importance here.

Monitoring systems that measure brain waves, oxygen, blood pressure, or body temperature require soft, flexible, and hygienic connectors with a high number of mating cycles. Silicone‐molded solutions can also withstand mechanical influences and are fail‐safe when transporting the respective devices. This ensures continuous monitoring of the patient.

In the field of robot‐assisted surgical aids, the cable connections are exposed to varying loads such as tension or torsion. In this case, Silicone-overmolded System Solutions offer optimum mechanical robustness and thus failure protection and reliability – while also meeting the strictest hygiene standards.

Many applications in the field of dental equipment require hybrid connections with a parallel supply of water, electricity, air, or light. Silicone-overmolded System Solutions are suitable for a wide range of hybrid connections and allow easy‐to‐clean Cable Assemblies thanks to their non‐sticky surface.

We take care of the medical testing and documentation for the assembled systems. This saves you time and development costs.

We work with you to develop a solution that perfectly meets your requirements. From planning and production to cable assembly: We combine all competencies under one roof and can also implement customized solutions for your project.

Silicone is used whenever resistance to mechanical shocks, thermal stability, autoclavability, and high bending fatigue strength are required. This is typically the case in medical applications – endoscopes, robotic systems, dental technology, and diagnostic imaging systems.

This technology is available for the ODU MEDI‐SNAP® Plastic Circular Connectors and for the ODU MINI‐SNAP® and ODU AMC® HD Metal Connectors. Silicone overmolding is also possible for customized product solutions.

Our silicone‐overmolded system solutions can withstand wipe disinfection as well as machine cleaning with neodisher® MediClean Forte. These complete systems are designed to be cleaned in an autoclave at 134°C and a pressure of 2 bar. Their surface properties will remain unchanged for up to 500 autoclaving cycles.

The stick‐slip effect results in unwanted adhesion to other objects or, for example, the skin of a patient. This effect is prevented by means of a special surface treatment that gives our cables, including the overmolding, a non‐sticky surface with a pleasant feel. This smooth silicone surface provides a permanently improved grip and feel without wear or abrasion, even after autoclave cleaning.

Yes, our cables including the overmolding, with which the patients could come into physical contact, are tested in accordance with DIN EN ISO 10993-5.

We perform numerous tests that are required for applications in the field of medical technology, both in our own laboratory and at certified external facilities. Hygiene, durability as well as patient and user protection are the top priorities. Our silicone‐overmolded system solutions are also subjected to cytotoxicity testing in accordance with DIN EN ISO 10993-5. The documentation and reports from these medical tests are available to our customers.

As standard, the outer shell of the cables consists of platinum-cured silicone in the colors white, gray, or black.

By sourcing your complete system from ODU, i. e., the connectors, cables, and the overmolding, you save valuable time in your development phase because the pre‐qualification of the cable overmolding (adhesion, mechanical and medical tests, manufacturing parameters) has already been completed by us in partnership with well‐known cable manufacturers.